We used to hear about cold-stamped steel quite a bit, because it was the new way of forming these metals into car components. But as more cars adopt it, the less we hear about it. Unless, you go further than everyone else and maximise its advantage.

That’s what Mazda did (again) by announcing developing the world’s first cold-stamped car parts made from 1,310 MPa-class high-strength steel. Mazda didn’t do it themselves though as they worked together with Nippon Steel & Sumitomo Metal corporation and JFE Steel Corporation.

Parts made from this high-strength steel will be used in Mazda’s new-generation Skyactiv-Vehicle Architecture that will be adopted first by the all-new Mazda3.

The benefit of using high-strength steel is that carmakers are able to use thinner sheet metal while still ensuring strength. The result is a lighter vehicle which in turn improves fuel economy and allows for better vehicle handling. Naturally, it’s good for safety too.

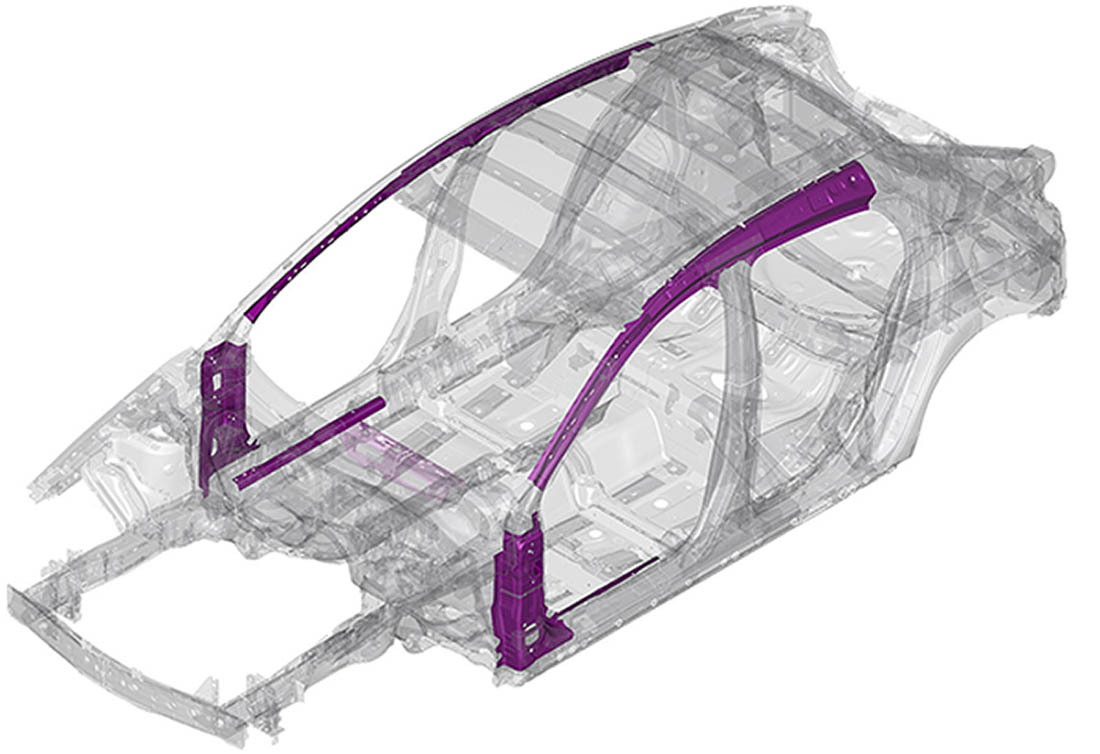

Cold-stamping of vehicle structure components has only been possible with 1,180 MPa or lower-classed steel. In the Mazda3, the cold-stamped 1,310 MPa high-strength steel will be used for the front pillar inner, the roof rail inner, the hinge pillar reinforcement, the roof rail reinforcement, the No. 2 crossmember and the side sill inner reinforcement, saving about 3 kilograms over the same parts in the previous model.