A closer look at the one-off Polestar built in 30 days

The Polestar 1 is a wonderfully Swedish super GT. But what happens if this refreshingly attractive hybrid coupe goes on a student exchange to the USA, develops psychotic tendencies, an S&M wardrobe and got into MMA? Well, something like this. Probably.

What you’re looking at is the crackers collaborative brainchild of digital wizard Khyzyl Saleem, car builder Daniel Covarrubius and EA Games. See, when EA (*deep voice* “It’s in the game”) needed a new halo car brought to reality for its upcoming instalment of Need for Speed, they called in this collabo.

If you didn’t spend your youth indoors slapping decals, underfloor neons and a cornucopia of crazy mods on to cars all to the sound of wastegate noises, NOS applications and Lil Jon & The Eastside Boyz, NFS is all about building crackers-looking modified cars. Only this time, EA decided to hit print and make one for real.

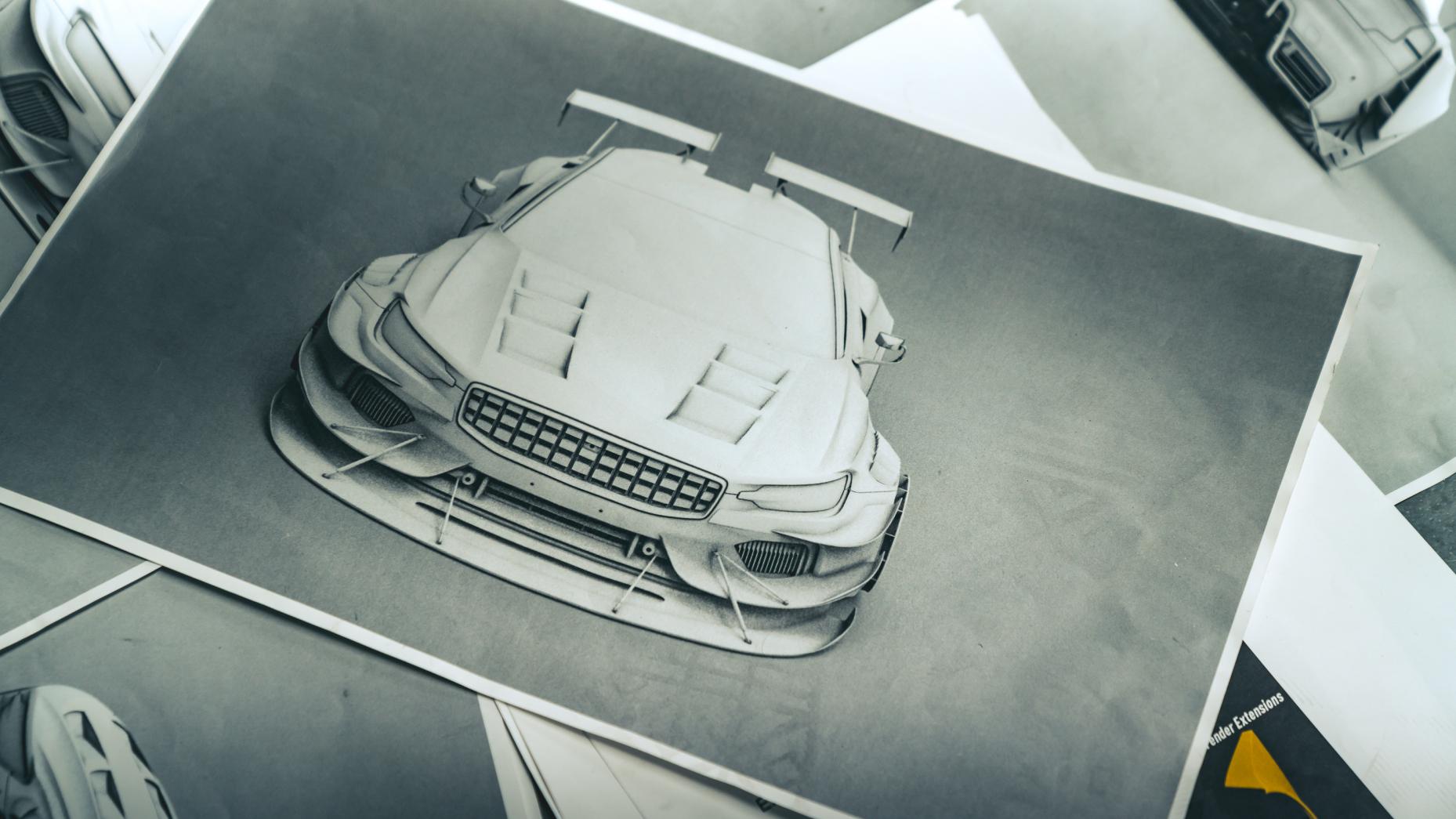

And it was quite the build. The whole car was rendered digitally first, just to see how much you could turn up the ‘bonkers’ knob on the bodywork. Looks like Khyzyl – who was responsible for all the 3D rendering – managed to find ‘11’ on that scale.

“The design and render took me around two days to complete,” Khyzyl told Top Gear. “Once I had a rough image in my head of what I wanted the car to look like, I started modelling a simple design and built upon it. I didn’t have any particular inspiration – I just wanted it to look wild. To be honest, I thought a Polestar was an unusual choice for an NFS game, it hadn’t been done before so I didn’t really know what to expect, so turning it into something aggressive was a really fun challenge.”

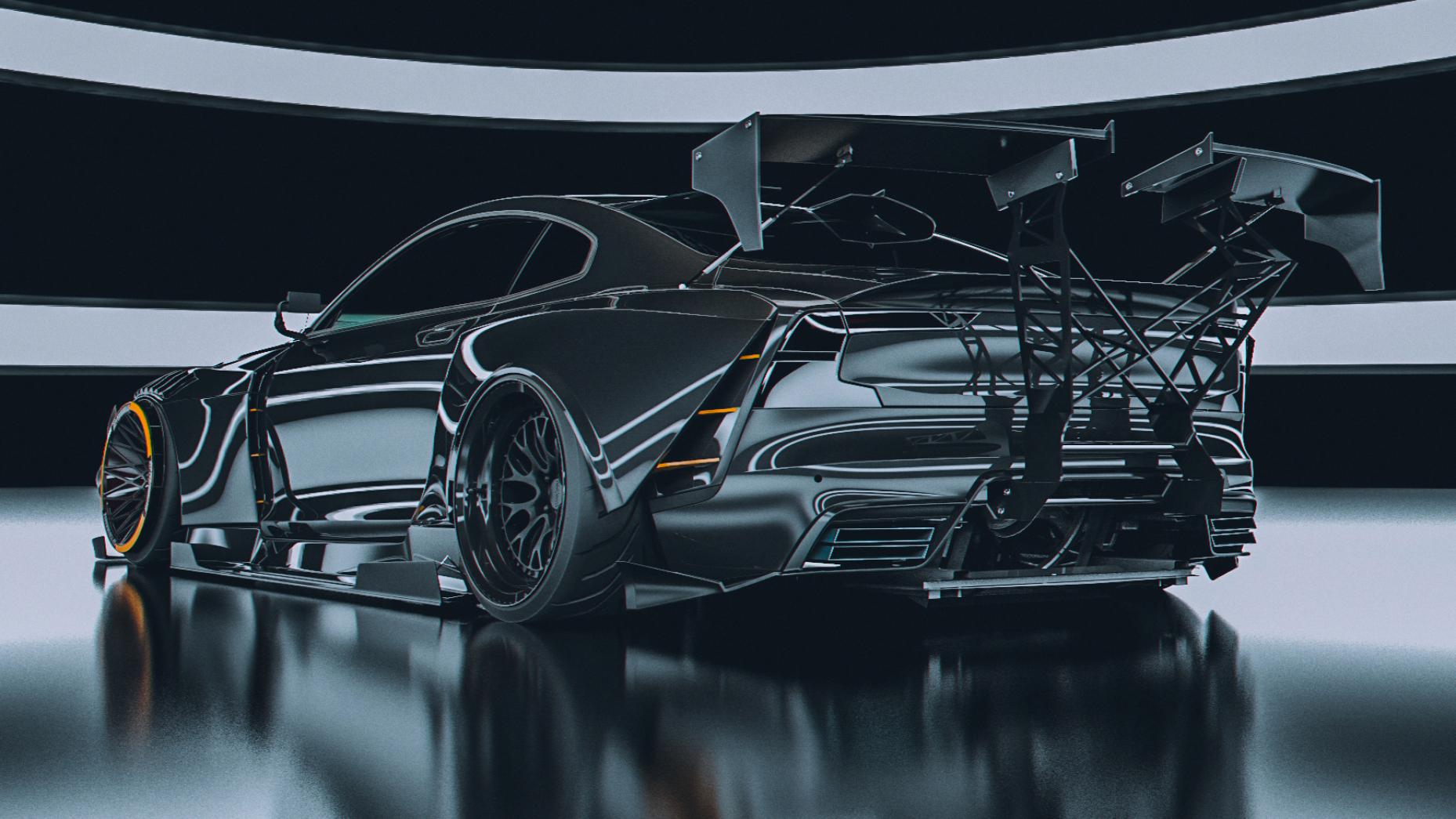

As you can see, he didn’t hold back. The bodykit is positively bananas. There are those huge guillotine-like canards up front, an ankle-hungry front splitter, widened front arches at the front and fat overfenders at the rear. Then there’s that spoiler. Or, more specifically, those spoilers. The twin wing arrangement is akin to the original Pagani C12 Zonda, just if they were on stilts and supported by scaffolding. As a visual statement, it doesn’t half grab your attention. And it’d be the perfect chin-up bar for a gym-obsessed DTM fan.

But designing a car in the fantasy land of a .PSD file is one thing, making it a reality is another. That was Daniel and his company Sekrit Studios’ problem. EA gave Daniel just 30 days to build the car from start to finish. Talk about squeaky-bum time. Especially as nobody’s modified a Polestar 1 before, there were no moulds, no 3D scanned parts, nothing. Literally the only thing Sekrit Studios had to work with was the render from Khyzyl. They had no idea on wheel sizes or offsets and no idea on how the Air Lift Suspension would fit either. It was so last-minute the car was air shipped over to him.

Luckily Sekrit are a seemingly industrious and indefatigable lot. The car arrived fairly disassembled, so they built it back up again and then got cracking on the bodywork. The standard Polestar is built out of quite a lot of carbon and carbon-fibre-reinforced polymer (parts of the chassis, the doors, bonnet and boot) to improve rigidity and lightness. Dan and his team just decided to add a lot more.

They literally built the arches, wings, splitter, everything on the car and purely by eye and eye only. For the likes of the arches, the process involved building a cardboard ‘skeleton’ underneath of how the rendered arches would look, before then laying carbon fibre over the top to give it the correct shape. Once the shape was sorted – and the carbon was hard/cured – they then cut out all the cardboard to leave behind the finished (but raw) part. Which is a lot harder than scrolling through a menu and hitting ‘X’ to confirm, like in the game.

Social media had its hand in the build too. Specifically, with the suspension. Flummoxed on getting the car on the ground, Dan scrolled through Instagram where he saw a modified Volvo V90 by a company called Sadistic Ironworks in LA. Dan clocked that the suspension struts looked quite similar to the Polestar struts, went round and managed to grab a set (expecting them to need some work to fit) and they turned out to be a direct fit. Bingo.

After 30 late nights, the car was done. And doesn’t it look crackers? Properly batsh*t and a bit childish, which is exactly what NFS is about. But what’s under the bonnet? Well, nothing. Because of the tight turnaround time, to stop the car being locked in customs, the 2.0-litre four-cylinder supercharged and turbocharged petrol engine (that drives the front wheels) and e-motors hybrid gubbins (powering the rear wheels) were removed.

But that doesn’t mean that they can’t be dropped back in and then given a little tickle. And given the standard car has 592bhp and 1001nm of torque, there’s plenty of room to get big numbers out of it. Plus, there’s already a glass box in the boot of the Polestar 1 as standard. A perfect place for the NOS bottle then.

What do you think of the build? Nostalgic or ‘butters bruv’?